Wood Products

Wood products are products made from harvested timber, such as timber frames, flooring, furniture and paper. These can contribute towards climate change mitigation by retaining carbon and by avoiding the need to manufacture materials that have a high greenhouse gas (GHG) intensity of production.

The UK Climate Change Committee (CCC) identified that increasing the safe use of wood products in construction is an important route for climate change mitigation and helping to achieve the UK’s net zero GHG emissions target by 2050.

In 2022, 10 million tonnes of green roundwood were removed from UK woodlands. These were used to create wood products, used as wood fuel, or were exported. As the UK consumes far more wood products than it produces (see Table 1). Imported wood products are a large component.

Sawnwood

(million cubic metres)

Wood-based panels

(million cubic metres)

Paper

(million tonnes)

Wood Fuel

(million oven dry tonnes)

Production

2.9

3

3.2

4.6

Apparent Consumption1

8.9

5.8

5.2

16.5

Table 1. Production and apparent consumption of timber products in the UK, in 2022.

Source: UK Wood Production and Trade: provisional figures – Forest Research (2024)

1Apparent consumption = Production + Imports – Exports

Click image to enlarge

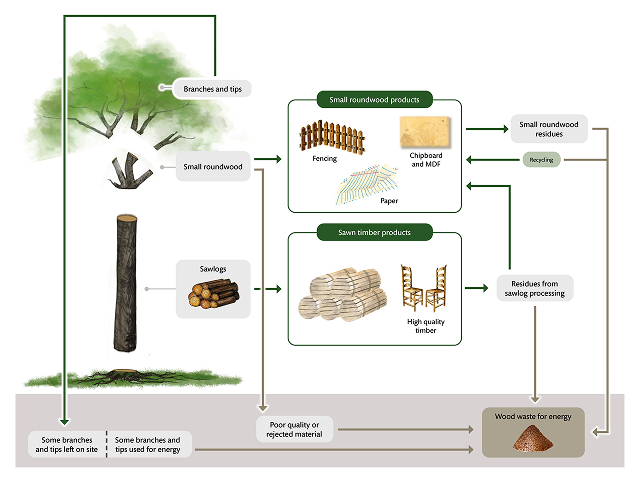

Figure 1. The Wood Product Carbon Pool. An example of the multiple products that can be harvested from forests, ranging from high value products and ranging in value are small roundwood products. Residues from wood processing can be recycled into other wood products, and often the residues can be used to generate energy. Harvesting residues can also be used for energy but often they are left on site.

The Wood Product Carbon Pool

The wood product carbon pool is the amount of carbon stored in wood products in use, which has been estimated to be around 140 million tonnes in the UK.

The carbon stored in an individual wood product can be determined by estimating the density and volume or the mass of the product and converting this into tonnes of carbon. The density and carbon content will generally vary by tree species.

Calculating the carbon stock and stock change in the total wood product carbon pool at a national or regional level needs to account for both inputs (gains) and outputs (losses) to the carbon pool on a national scale. As it is difficult to measure the carbon stock of wood products at a given point in time, this is usually determined via models.

The size of the wood product carbon pool depends on the balance of:

- Carbon gains, as new wood products are created. This is usually determined by harvesting rates, timber extraction from woodlands and national wood production statistics, and

- Carbon losses, where carbon within wood products is converted to carbon dioxide (CO2) or methane (CH4) when they are disposed of. This is determined by the length of time that products are in use (service life).

Harvested timber can be used to create a variety of products. Sawn timber may be used for construction frames, joists, floorboards or furniture, and may remain in use for many decades. Wood-based panels (such as MDF, OSB or chipboard) may also be used in construction, with a long service life, in furniture with a medium service life, or be used in packaging with a much shorter life. Paper and card tend to have a very short service life. In general, products which last a long time, such as timber used for construction, will store more carbon in the long-term.

In 2022 the Wood Recyclers’ Association estimated that UK wood processors handled 4.31 Mt out of 4.5 Mt of all wood waste generated, meaning only a small proportion was landfilled, or burnt in informal markets. Of the 4.31 Mt processed, an estimated 65% was used for energy generation. Approximately 24% was recycled into panel boards, resulting in the carbon being retained in wood products for longer. The remainder went for other uses such as animal bedding (8%) or was exported (3%).

Service Life of Wood Products

It can be particularly challenging to accurately determine the service lives of wood products, as these can be highly variable both within and between wood products, and between different countries.

The service life of a wood product can be highly influenced by changing demand and fashion for wood products, rates of re-use and recycling, and how they are disposed of at the end of their lifetime.

The UK follows international guidelines to calculate the rate at which wood products are discarded by applying a half-life for 3 different wood product categories (see Table 2). For example, a half-life of 25 years means that half of the original carbon remains in the wood product carbon pool after 25 years, a quarter of the carbon after 50 years, and so on.

Wood product category

Default half-life (years)

Paper and paperboard

2

Wood-based panels

25

Sawnwood

35

Table 2. IPCC default half-life values for wood product categories.

Source: Refinement to the 2006 IPCC Guidelines for National Greenhouse Gas Inventories, 2019

Benefits of Wood Products

Timber derived from sustainably managed woodlands can provide a low-carbon replacement for other materials, such as concrete and steel, that can only be produced with high GHG emissions from fossil fuels. The GHG emissions avoided through this substitution role of wood products can be significant and have the potential to make a greater long-term contribution to GHG emissions mitigation than the carbon retained in the wood products.

The extent to which wood products avoid GHG emissions when replacing non-wood products depends on the processing emissions for their manufacture being relatively small. There is growing interest in the development of engineered wood products to diversify the applications of wood and to increase the quantity of harvested wood that can be utilised for high-specification, long-life applications such as structural support in buildings. However, there is limited information about the processing emissions involved in the relatively intensive manufacture of engineered wood products, therefore further research may be needed to understand the GHG mitigation benefits of these more innovative materials.